5 Jun 25

FACE OFF: BedBoss vs. Spray-In Liners vs. Rubber Mats: Which Comes Out on Top?

A pickup’s bed takes the brunt of the abuse—whether you're hauling equipment for work or gear for a weekend trip. So protecting it isn’t just a nice-to-have; it’s essential. From classic rubber mats to permanent spray-in liners, there’s no shortage of options.

So how does the all new BedBoss stack up against the usual suspects? We compared BedBoss, spray-in liners, and rubber mats across six key categories—Durability, Protection, Maintenance, Weight, Installation, and Cost—to find out which option fits your needs best.

So how does the all new BedBoss stack up against the usual suspects? We compared BedBoss, spray-in liners, and rubber mats across six key categories—Durability, Protection, Maintenance, Weight, Installation, and Cost—to find out which option fits your needs best.

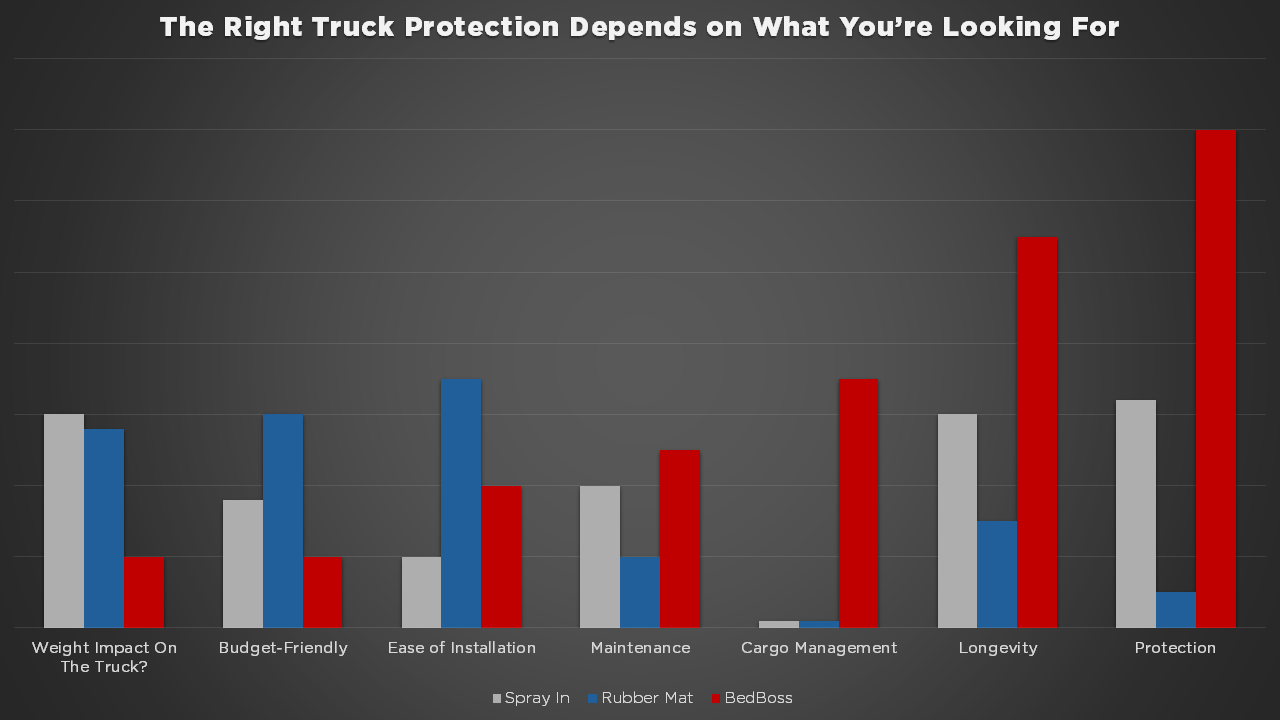

Protection — Winner: BedBoss

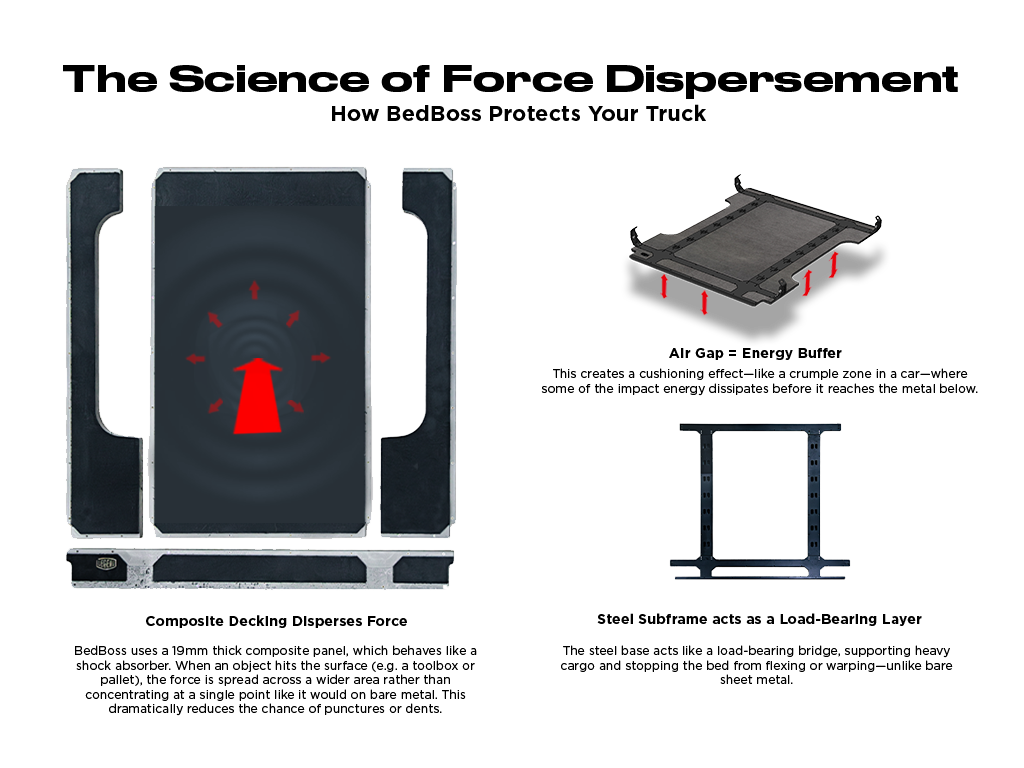

Each option protects in its own way—but BedBoss brings something the others can’t: structural defense. Its rigid composite deck absorbs and distributes impact force, protecting against serious dents and punctures. Drop a toolbox or cinder block? The truck bed underneath stays untouched.

Spray-in liners do a great job resisting scratches and corrosion. Their textured coating helps prevent cargo from sliding around and fends off scratches, rust, and corrosion. But while they protect the surface, they don’t reinforce the structure. Drop something heavy, and you might keep the liner intact but dent the metal underneath. This is the key difference between a structural floor that can absorb the hits vs a spray-in with your bed exposed.

Rubber mats are basic and good for basic protection. Good for small impacts and easy to replace, sure—but they can tear under sharp edges or heavy loads. And they offer no structural support. For serious protection, BedBoss is in a league of its own.

Longevity— Winner: BedBoss

Over time, truck beds take a beating—not just from big impacts, but from the constant grind of loading, unloading, and shifting cargo. This is where wear & tear resistance becomes a key factor in long-term performance.

BedBoss shines here. Its industrial steel subframe and 19 mm composite surface don’t just absorb damage—they resist the daily grind. Unlike coated surfaces that can scratch or degrade, BedBoss maintains its structure and finish through years of repeated abuse. Contractors, fleet managers, and heavy haulers can count on it to stay intact even under harsh, high-frequency use.

Spray-in liners are not bad for long-lasting either. Their textured coating bonds directly to the metal, preventing rust and standing up well to abrasions, shifting tools, and messy cargo. However, with time and use, they can fade under UV exposure or wear thin in high-traffic areas—especially if you frequently toss in gravel, concrete, or sharp tools. Repairs require professional resurfacing.

.png)

Rubber mats do a decent job resisting surface wear. They’re thick, UV-stabilized, and affordable to replace. But over time, sharp edges and friction can cause tearing or deformation. For casual users, they’re more than enough. For high-use commercial trucks, though, they may wear out faster than the alternatives.

Maintenance & Upkeep — Winner: BedBoss

When it comes to keeping your truck bed in top shape with minimal effort, BedBoss strikes the smartest balance. Its chemical-resistant composite surface is easy to clean—just sweep or rinse like you would with a spray liner.

But unlike bonded coatings or mats, BedBoss is also modular and fully removable.

When deeper cleaning is needed, just unbolt four D-rings and lift it out in under 10 minutes. That means you can get to the factory bed, clean underneath, and reinstall it without special tools or a trip to the shop.

Spray-in liners come close—they’re bonded directly to the bed, so there’s nothing to shift or trap debris. Day-to-day maintenance is a breeze. But over time, UV exposure can cause fading, and gouges or worn spots may require professional resurfacing to restore the protective coating (MotorTrend). While infrequent, these fixes can’t be done at home and may involve downtime at a liner shop.

Rubber mats are easy to remove and clean, but they require more frequent attention. Dirt, grit, and moisture can accumulate underneath, especially in wet climates or during winter. If ignored, this can lead to rust or paint damage. Regular lifting and cleaning is essential—and while mats are cheap to replace, they’re more work to maintain properly.

Weight Impact — Winner: Spray-In Liner

If weight is a concern—especially for fleet trucks or vehicles near their GVWR—spray-in liners are your lightest option. A typical liner adds just 40–70 lbs, barely more than a full tank of gas (MotorTrend).

Rubber mats are heavier, with most weighing 30–50 lbs depending on bed size. Not back-breaking, but something to consider.

BedBoss is the heaviest of the three. Its steel frame and thick composite decking can push the added weight to ~120 lbs—roughly the same as an extra passenger. That’s the trade-off for its unmatched strength.

Cargo Management — Winner: BedBoss

Most factory truck beds come with a limited number of anchor points—usually four to six D-rings at best. That’s often not enough when you're hauling irregular loads, equipment, or anything needing multiple tie-down angles. BedBoss solves this by more than tripling the number of secure anchor points, thanks to its integrated rail system and strategically positioned mounting slots. This gives you far more flexibility for using ratchet straps, bungees, or netting—without relying solely on the factory D-rings or aftermarket hacks.

Whether you're hauling a generator, stacked materials, or awkwardly shaped gear, BedBoss makes it easy to strap everything down tightly and confidently. For fleet vehicles and contractors, this isn't just convenient—it’s a matter of safety and compliance.

Spray-in liners, by contrast, don’t improve cargo management at all. They coat over the factory bed and existing tie-downs, but don’t add any new points. If your cargo shifts or doesn’t align with the existing anchors, you’re out of luck unless you install aftermarket hardware. Rubber mats offer decent grip under cargo to reduce sliding, but they don’t add tie-downs either—and can even make existing ones harder to access if the mat overlaps or covers them.

Ease of Installation — Winner: Rubber Mat

.png)

If installation is your top priority, rubber mats are as plug-and-play as it gets. Just roll the mat into your truck bed—no tools, no prep, no sweat.

Most are designed to fit your truck’s contours right out of the box, and even universal mats can be trimmed with a basic utility knife.

The whole process takes five minutes tops, and removal is just as simple.

At around 30–50 lbs, they’re not feather-light, but most people can handle it solo.

Spray-in liners, on the other hand, are the most labor-intensive option. They even require professional installation involving surface prep, masking, spraying, and curing.

That means your truck is in the shop for a day or more, and there's no DIY shortcut unless you're willing to invest in gear and risk a lower-quality finish.

Factory-applied spray-ins eliminate this hassle if ordered with a new truck, but purely in terms of ease? Spray-ins land at the bottom.

BedBoss sits right in the middle. It doesn’t require any drilling and uses existing mounting points like D-ring holes for a fully bolt-in install. All you need is a wrench, a second set of hands, and about 30–60 minutes. Guided install videos make the process straightforward even for first-timers. It’s not a five-minute job like a mat, but compared to spray-ins, it’s way more approachable, DIY and completely reversible.

Cost — Winner: Rubber Mat

Rubber mats are the most affordable option by far. Basic versions start around $50, with high-quality, vehicle-specific ones typically ranging from $150–$200. Even premium systems like Tmat stay under $1,000, making mats an easy win for budget-conscious owners or fleet operators. They’re also cheap to replace if damaged.

Spray-in liners fall in the mid-range, usually costing $350–$700 with professional installation. Some trucks include them from the factory, and DIY kits are available for less—but results vary. If the liner fades or gets gouged, repairs can be costly and require a return to the shop.

BedBoss is the premium choice at around $1,900, but it offers much more than surface coverage. With its structural reinforcement, added tie-downs, and modular design, it’s a smart long-term investment for those who use their trucks as serious work tools—not just cargo haulers.

Verdict: Which Bed Liner Is Right For You?

Choosing the right bed protection comes down to how you use your truck—and what you expect from it.

If your truck works hard, BedBoss is the upgrade it deserves. With a steel subframe, 19 mm composite surface, and built-in tie-down rails, it doesn't just protect your bed—it reinforces it. From heavy gear to fleet use, BedBoss adds the strength and utility to handle real work.

Spray-in liners suit drivers who want a clean look and long-term surface protection—but don’t need structural support. They resist scratches and rust, but won’t stop dents from heavy impacts, and repairs require professional resurfacing.

Rubber mats are the budget pick. They’re easy to install and offer basic floor protection, but lack wall coverage and long-term durability. Best as a low-cost add-on or for light, casual use.

Verdict:

Contractors, fleets, and serious users should go with BedBoss—the only option that reinforces your bed while adding real utility.

Spray-ins are for light-duty users who care more about aesthetics and longevity than actual impact protection.

Rubber mats are best for minimalists or budget-conscious drivers who want basic coverage with no frills.

Whatever your use case, if you expect more from your truck, BedBoss is the only solution designed to deliver more in return.

Share Article