4 Jun 24

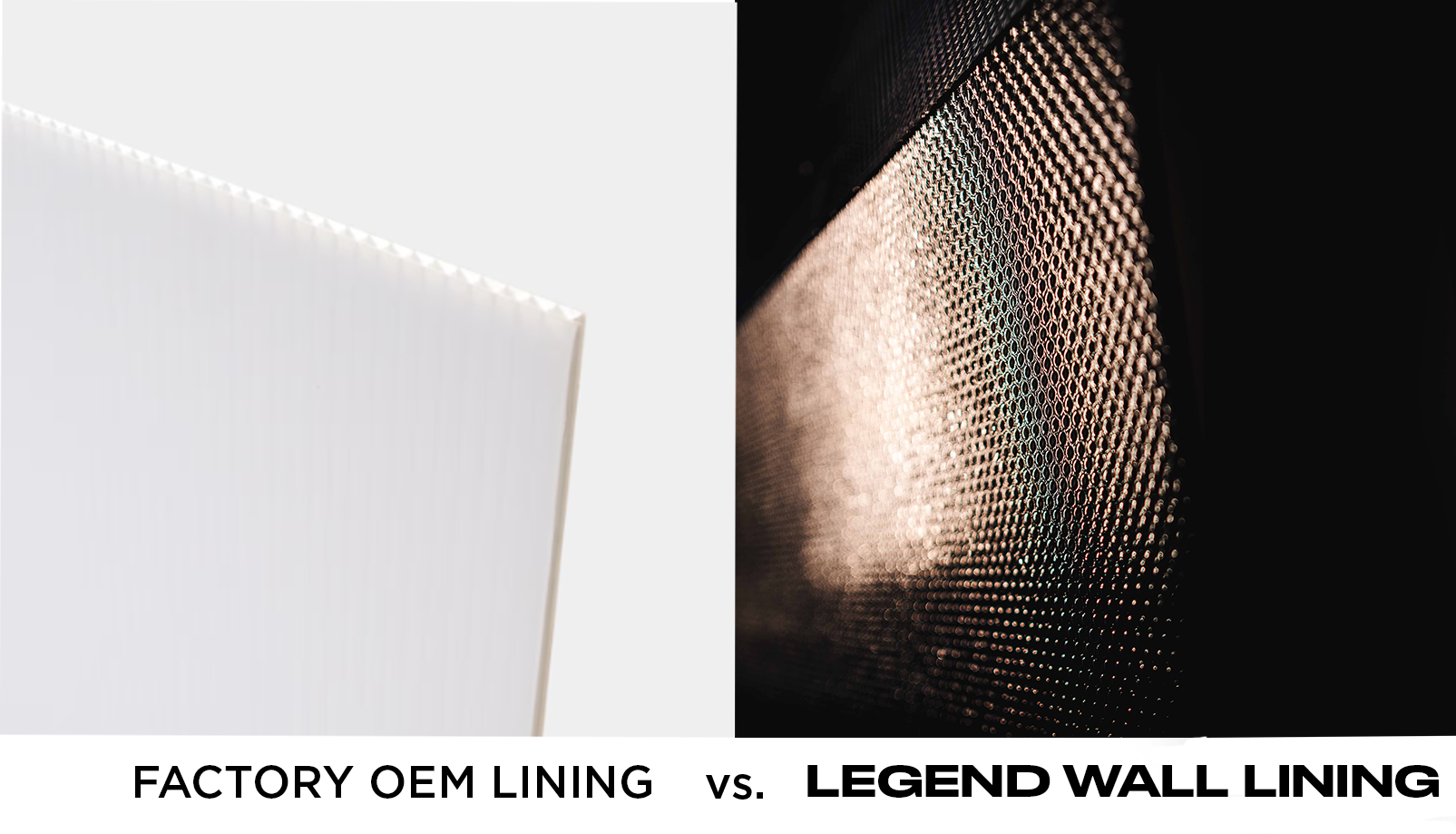

Face Off: Ford Transit Factory (OEM) Liners vs Legend Wall Liners

You’ve just purchased a new transit van from Ford, eager to hit the road and start visiting your customers. The vehicle looks fantastic, and inside the cargo area, you see the shiny black factory-installed wall liners. You might think, "I don’t need an upfit; my van already has liners!"

Those factory wall liners, whether jet black or stark white, are OEM add-ons designed to cover the bare metal ribbing of the walls. But should you stick with the factory OEM liners, or is it worth upgrading to composite lining?

Let’s break down the characteristics that matter most for the longevity and efficiency of your van, comparing factory products to Legend’s tailored solutions.

Price: Factory OEM

Price: Factory OEM

There’s no question about it, Factory OEM liners are cheaper.

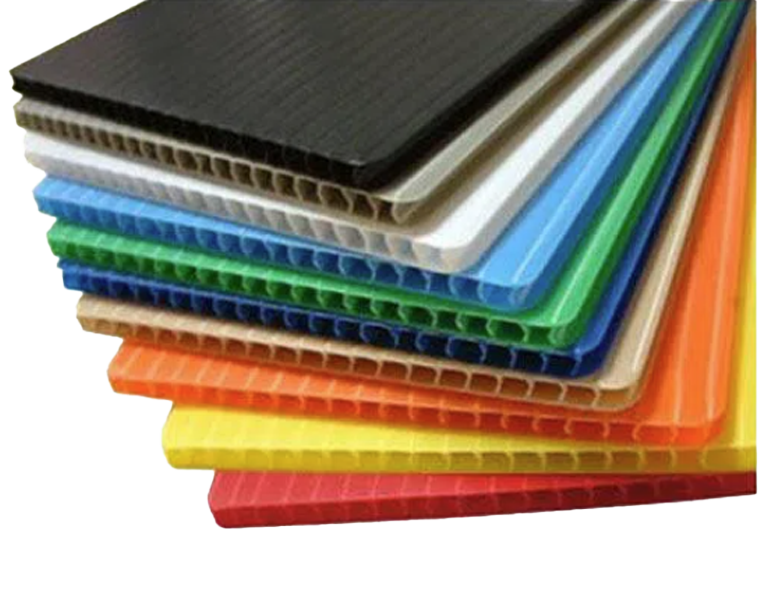

They come pre-installed at no additional cost and can save you money in the short term by providing some basic protection. In fact, that’s why Ford equips them in all of their stock vans. It’s a cheap solution for them to keep costs down. Corrugated plastic - which the OEM liners are made of - is extremely cheap to produce and purchase. Though the cheap cost of production comes with an inherent drawback for quality and durability, the plastic does allow for a very affordable lining option for your Ford Transit.

In the short-term, it’s impossible to beat the affordability of OEM liners. However, as time goes on the drawbacks of factory liners become glaringly obvious. If you’re looking for long-term preservation of your van, don’t rely on the protection of OEM liners. They will quickly become obsolete.

Durability: LEGEND

Coroplast can be quite thin. At low temperatures, the plastic becomes brittle, while at high temperatures, it softens. Both scenarios lead to frequent cracks and breaks. To make the plastic last, you’re obligated to be overly cautious and timid, which just isn’t practical when you’re working on the road day in and day out.

The difficult part isn’t even the incurred damage though, it’s the unnecessary headache of replacements. Once you incur damage to your liner, you’re left with the task of physically ripping out those damaged liners yourself. Then, you must shop for new wall liners, which wastes precious time finding an upfitter while you could be visiting customers and making money.

It’s time-saving to get a durable liner from the get go.

Composite wall liners are the far better option here for many reasons.

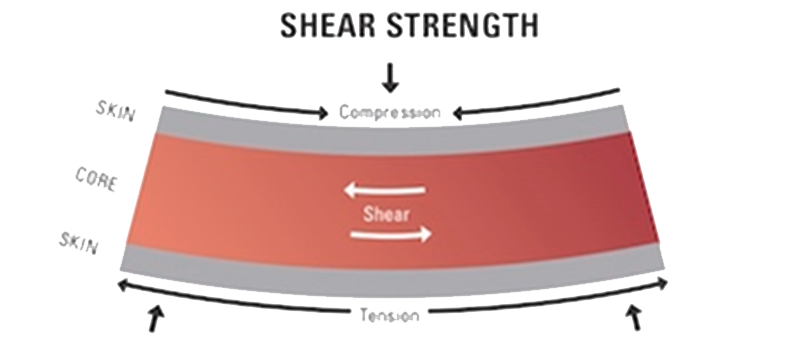

Firstly, Legend’s Duratherm has a higher thickness of 6 mm, compared to typical 3.9 mm OEM sheets. Moreover, rather than corrugated plastic, Duratherm uses an advanced honeycomb polypropylene structured material with foiled foam & fiberglass. The panel works like an I-Beam, with the core being the vertical element and the facing being the flange, working together to create high shear strength.

To put it simply, the thick core creates significantly superior strength which is further enhanced by Legend’s integration of foiled foam & fiberglass.

This is a way more complex design than single-layered coroplast, which makes all the difference in longevity & the ability to sustain wear & tear.

This is a way more complex design than single-layered coroplast, which makes all the difference in longevity & the ability to sustain wear & tear.

Duratherm lasts forever, unaffected by temperature and unbothered by your hard work, in stark contrast to Ford’s factory linings which are much quicker to break.

Versatility: Factory OEM

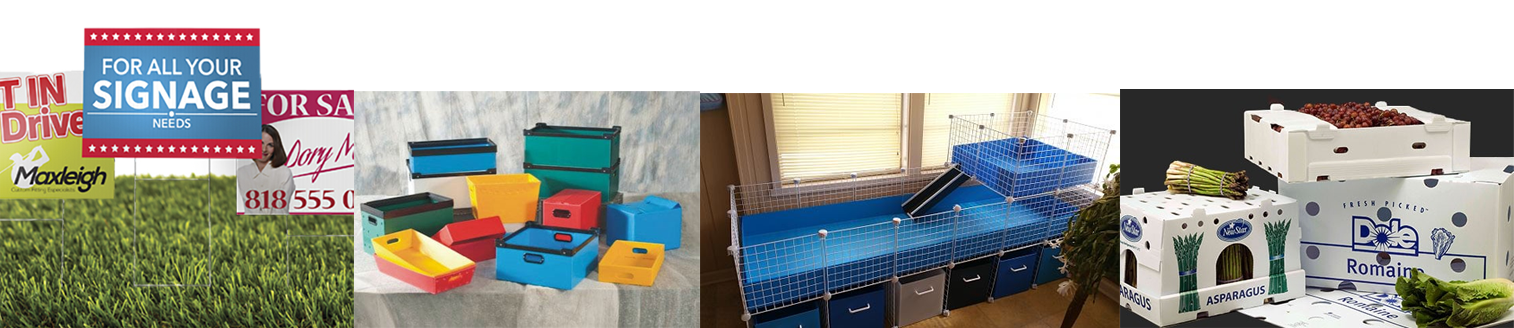

Do you know what coroplast is used for? Everything under the sun.

That’s not a joke, here’s what plastic companies advertise the applications as: “signboards, packaging, fabric lamination, pet enclosures, event display stands, building templates”.

Anything that requires hard plastic can use coroplast, the most common usage being that of outdoor signs. Now if you’re looking for something you could reuse in many ways, you’ll find that the Factory OEM plastic is the clear winner.

But are you really looking for something to reuse again?

There is a clear trade-off at play here, given that the jack of all trades tends to be a master of none. Coroplast is versatile because it isn’t specialized for any particular use, but instead it is generalized for many uses.

There is a clear trade-off at play here, given that the jack of all trades tends to be a master of none. Coroplast is versatile because it isn’t specialized for any particular use, but instead it is generalized for many uses.

Most of such uses, commercial drivers are never going to be concerned about in the cargo van industry. All you need is just something to actually protect your Ford Transit.

After spending all this money on your Ford, do you feel comfortable using the same material that’s used for lawn signs to protect your interior?

Protection: LEGEND

Unlike corrugated plastic, Legend liners’ material is developed with a very clear & singular purpose in mind: to improve the ride for work van drivers.

There is a clear advantage to products designed by manufacturers who specialize in van safety. In addition to the previously mentioned durability capabilities, composite lining solutions prevent van dents & damage, increasing the longevity of your vehicle.

Ford Transits are well-renowned for reliability, travelling up to 300k miles if taken care of. Given coroplast’s brittle nature with little to no protective properties, there is high risk of tanking the residual value of the vehicle by the end of its long lifespan.

Ford Transits are well-renowned for reliability, travelling up to 300k miles if taken care of. Given coroplast’s brittle nature with little to no protective properties, there is high risk of tanking the residual value of the vehicle by the end of its long lifespan.

Composite lining solutions not only preserve the van’s value, but also safeguard it against the hustle and bustle of daily work. Designed to be impact-resistant, chemical-resistant, moisture-resistant, and rot-proof, composite linings are an essential solution for long-term interior protection.

Weight: TIE

Both factory OEM linings and composite lining solutions like Legend are extremely lightweight. Neither is going to have a substantial impact on your riding experience.

Besides its effects on the ride, weight is also a very important factor to keep in mind when considering fuel efficiency.

This is doubly true for electric vehicles, where battery range directly impacts your bottom line. This was the case for Riverford, which saved about $2.15 million CAD through weight-reductions for their fleet.

This is doubly true for electric vehicles, where battery range directly impacts your bottom line. This was the case for Riverford, which saved about $2.15 million CAD through weight-reductions for their fleet.

For this part, both liners meet the challenge.

Insulation: LEGEND

Factory OEM liners are single layer coroplast sheets without insulation. It means there will be no noticeable difference between outside and inside temperatures with factory linings.

This can be a real problem in changing weather conditions. Beyond sensitive cargo, consider plumbers struggling with freezing tools or service technicians handling scorching hot equipment. It’s an uncomfortable and difficult environment to be in, consider the difficulty of having to work inside such a van.

Honeycomb polypropylene, like the one used by Legend, is designed to minimize climate effects and provide thermal protection. Due to the inherent thermal management properties of polypropylene, enhanced with the foiled foam used by Legend, Duratherm offers significantly better value than factory OEM linings.

Noise Reduction: LEGEND

Factory OEM liners provide minimal noise reduction due to their thin, single-layer construction. The corrugated plastic does little to absorb sound, resulting in a noisier ride and a less comfortable working environment. On the other hand, Legend's composite liners are designed with multi-layered materials that significantly dampen noise.

In a study by Lou et al. (2016) from the Journal of Industrial Textiles, it was found that polypropylene composites absorb 94.2% acoustic waves at 2000 hz or above. To provide you with some context, road noise while driving typically hovers from 700-1300 hz. Legend products absorb all of that!

So basically, we’re dealing with heavy noise reducing liners vs single layer plastic that lets you hear all the traffic noise you don’t want to hear. Legend is undoubtedly the better option in this regard.

So basically, we’re dealing with heavy noise reducing liners vs single layer plastic that lets you hear all the traffic noise you don’t want to hear. Legend is undoubtedly the better option in this regard.

Sustainability: LEGEND

Sustainability is a very important factor to consider.

As responsible business professionals, environmental concerns are a rising trend, pushing them to the forefront of business decision-making. Customers are increasingly interested in protecting the environment, which means people notice your reduced carbon footprint. For any fleet, this is an important competitive advantage, along with a way to show your commitment to both customers and the environment. The importance of investing in sustainability is only increasing as regulations consistently seek to demand lower & lower emissions.

In this aspect, both lining options make considerable efforts. Corrugated plastic is known to be way better than normal plastic options as it’s easily recyclable, but at the same time, it’s non-biodegradable. This means that every time you rip out and replace OEM liners after they inevitably wear out, you’re adding plastic to a pile that’ll one day end up in a landfill.

Legend liners are made with 75% sustainably sourced materials, designed to last forever and still be recyclable.

Legend liners are made with 75% sustainably sourced materials, designed to last forever and still be recyclable.

There is a massive difference here in waste contribution, which plays a significant role in sustainability. Picture the mountains of tossed corrugated plastic compared to the one Duratherm kit you’ll throw out at the very end of your Ford’s lifecycle.

Legend is significantly better for the environment.

Overall: LEGEND

Factory liners, while cost-effective and versatile, lack durability, protection, insulation, noise reduction, and sustainability. Legend's composite wall liners offer a robust and specialized solution which adds significantly more value to your van, like it did for Robert.

Robert Machado is a passionate filmmaker and a fellow Ford Transit driver.

In the video below, Robert discusses his experience upfitting his Ford with Legend and also the impact it’s had on making his life easier.

Share Article

Related news

View all

Ford Transit Factory Mats vs. Legend Rigid Floors

With a newly purchased Ford Transit for your business, you may be thrilled that it includes a new factory mat in the cargo area. Give it a couple weeks, and you might think differently!

Top 5 Reasons why Legend is NOT a Fit for Me

Our solutions prioritize safety, vehicle preservation, noise reduction, and climate control. If these aren't your top priorities, our offerings may be more than you need.

How Van Upfitting Keeps Your Fleet Employees Safe & Happy

Van upfitting transforms your fleet into a safer & more efficient workplace by boosting employee morale, safeguarding well-being, reducing turnover, and driving productivity.